Liam Armstrong left school and joined the armed forces then started at Gestamp as a temp but was laid off when they had a downturn. Liam joined DPE and was made permanent as soon as possible. Liam has trained on several presses and is now one of the key setters running the new Seyi 500 and 600 ton presses. “Arlington is delighted that Liam has decided to remain as an Army Reserve and has our full support.” said Steve Dale General Manager. Liam previously a Royal Engineer in the Regular Army (2008-2011) recently applied and was accepted into the Army Reserves as a REME (Royal Electrical and Mechanical Engineers) soldier. His family are very supportive and his Army Reserve career choice, which also fits well with his commitment to his partner and growing family. His employer Arlington actively endorse employment from the Armed Services. He now attends Drill Nights on Tuesday in Aycliffe and the occasional weekend, where he continues to develop and train in his chosen trade, Recovery Mechanic. This is in the footsteps of his father, who is a long serving member of 124 Recovery Company as a Recovery Mechanic – like father like son. Arlington Supervisor Frank Hewitt worked in glass as a Production Manager for 21 years. He started as a Supervisor at what was DPE Automotive. In 2011 after a factory in Germany burnt down, we made seating assemblies for Nissan at Sunderland. In 2012 he was appointed Factory Supervisor and in 2014 became Production Manager. Since then changes to the culture through 5S and lean techniques, the company is now profitable with a happy workforce for which Frank is personally proud. “I cannot wait to get to work on a morning and work with them, we are all optimistic about the future here now as part of the Arlington Group of companies” said Frank. Arlington Automotive NE formerly DPE is one of the UK’s only independent “one stop shops” for automotive component pressing / welding / painting / assembly of products to UK OE manufacturers and their suppliers. Operating from NE of England with logistics hubs in other sites across the UK. Employees number around 100 offering a range of services and products: Pressing up to 600T (Progression and transfer). Mig Welding and Resistance welding (Single & Double Robots). ED Painting (1000hrs) and Powder Coating (480 hours). Assembly.

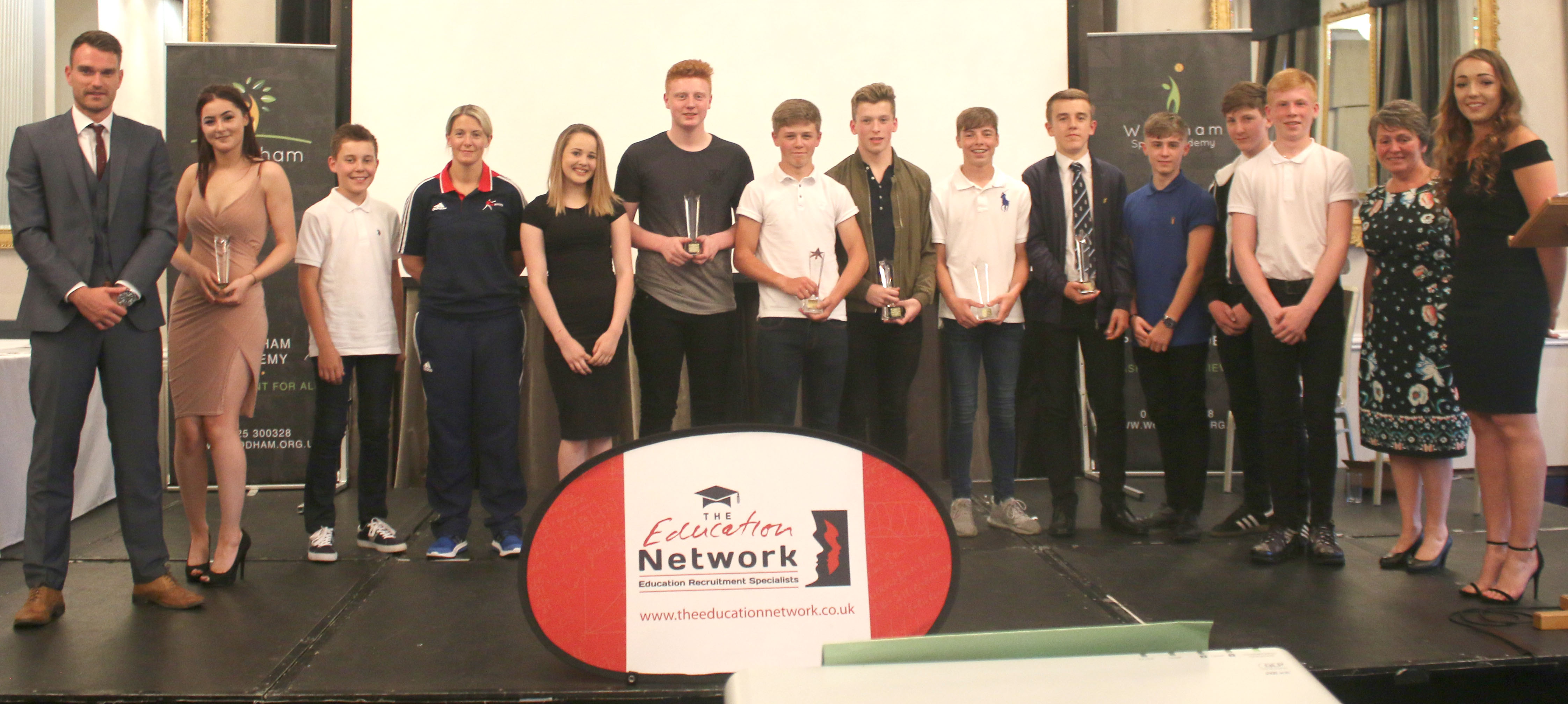

In Photo: Left to right: Frank Hewitt, Reservist Liam Armstrong, LCpl Army Recruiter Sarah Orton, W.O. Darren Rhodes